What if your refrigerator was twice as effective and completely silent?

APL chess movies have almost double refrigeration efficiency. Evolutionary materials could transform cooling and energy harvesting technologies.

Johns Hopkins scientists Applied Physics Laboratory (APL) in Laurel, Maryland, have created a new thermoelectric refrigeration system that is simple to make and twice as effective as devices built with standard thermoelectric materials. As the overall need for compact, reliable and energy -efficient cooling technologies continues to increase, this development offers a promising alternative to conventional refrigeration based on the compressor.

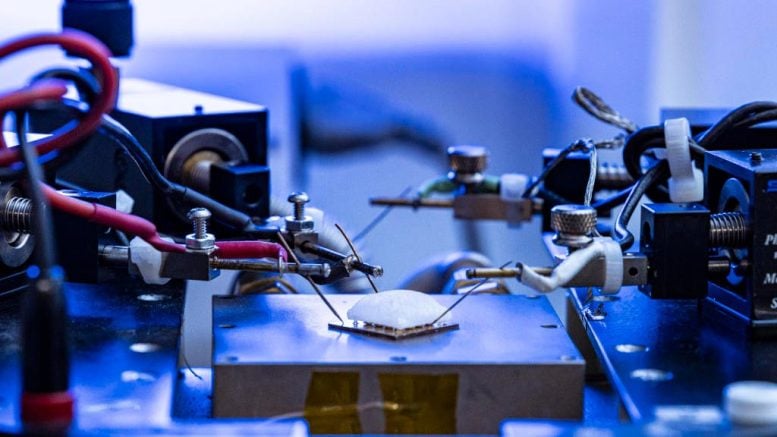

In a study published in Nature communicationsAPL researchers, working with Samsung Research refrigeration engineers, have demonstrated significant improvements in the efficiency of heat pump and cooling capacity. These gains were made possible through high-performance nano-designed thermoelectric materials developed in APL, known as superlatice structures (failures).

The chess platform represents the culmination of a decade of APL research on the advanced thermoelectrics of nano-ingenients and their applications. Originally designed for national security purposes, the equipment has since been adapted for other uses, including non -invasive cooling therapies for prostheses, and was recognized with an R&D 100 price in 2023.

“This real world demonstration of refrigeration using new thermoelectric materials highlights the capacities of thin nan-gegered chess films,” said Rama Venkatasubramanian, principal researcher of the joint project and chief technologist of thermoelectrics at APL. “It marks a significant jump in cooling technology and opens the ground to translate the progress of thermoelectric materials in practical, large -scale and energy efficient refrigeration applications.”

A new reference for solid state cooling

The demand for smaller and more effective cooling technologies is driven by population growth, urban expansion and increasing dependence on advanced electronics and large -scale data systems. Although traditional cooling methods are effective, they tend to be bulky, consume significant amounts of energy and rely on chemical refrigerants that can damage the environment.

Thermoelectric refrigeration offers a promising alternative. This approach transfers heat using electrons in specialized semiconductor materials, eliminating the need for mobile parts or chemical coolers. As a result, these systems can be made compact, silent, reliable and environmentally friendly. Although thermoelectric materials in bulk are already used in small products such as mini-reproductors, their low efficiency, their limited heat transfer capacity and poor compatibility with the manufacture of semiconductor chips have restricted their adoption in larger and high performance applications.

In the study, the researchers compared refrigeration modules using traditional bulk thermoelectric materials with those using thin layout materials of standardized refrigeration tests, measuring and comparing the electrical energy necessary to achieve various cooling levels in the same commercial refrigerator test systems. The Samsung Research Life solution team, led by the executive vice-president JOONHYUN LEE, collaborated with APL to validate the results thanks to detailed thermal modeling, by quantifying thermal charges and the thermal resistance parameters to ensure a precise performance assessment under real conditions.

The results were striking: using chess materials, the APL team obtained an improvement of almost 100% of efficiency compared to traditional thermoelectric materials at room temperature (about 80 degrees Fahrenheitor 25 c). They then translated these gains in the materials in an improvement of almost 75% of the efficiency at the device in the thermoelectric modules built with failure materials and an improvement of 70% of the efficiency in a fully integrated refrigeration system, each representing a significant improvement compared to the thermoelectric devices in loose. These tests were carried out under conditions which involved significant quantities of heat pumping to reproduce practical operation.

Scale

Beyond improving efficiency, chess technology with thin layers uses remarkably less material – only 0.003 cubic centimeters, or almost the size of a grain of sand, per unit of refrigeration. This reduction in the material means that APL’s thermoelectric materials could be mass produced using semiconductor chip production, resulting in a profitability saving and allowing generalized adoption of the market.

“This thin layer technology has the potential to develop from small-scale refrigeration systems to support large construction CVC applications, similar to the way lithium-ion batteries have been put to the scale of food devices as small as mobile phones and as large as electric vehicles,” said Venkatasubramanian.

In addition, chess materials have been created using a well -established process commonly used to make high -efficiency solar cells that feed trade satellites and LED lights.

“We used the chemical steam deposit in metal-organic metal (MOCVD) to produce chess materials, a well-known method for its scalability, profitability and capacity to support manufacturing at large volume,” said Jon Pierce, a main research engineer who leads the growth of the MOCVD to APL. “The MOCVD is already widely used commercially, which makes it ideal for the failure of the production of thermoelectric materials with thin chess layers.”

Future applications and energy harvest

These materials and devices continue to judge promising for a wide range of energy and electronics harvesting applications, in addition to recent refrigeration progress. APL plans to continue to associate with organizations to refine thermoelectric chess materials by emphasizing the effectiveness of the increase in efficiency to approach that of conventional mechanical systems. Future efforts include the demonstration of larger -scale refrigeration systems, including freezers and the integration of methods based on artificial intelligence to optimize energy efficiency in compartmentalized cooling or distributed in refrigeration and CVC equipment.

“Beyond refrigeration, failure materials are also able to convert temperature differences, such as body heat, in usable power,” said Jeff Maranchi, head of the exploration program in the APL research and exploratory development area. “In addition to advancing new generation tactile systems, prostheses and interfaces of human machine, this opens the door to evolutionary energy evolution technologies for applications ranging from computers to space vessels – capacities that were not achievable with older thermoelectric devices.”

“The success of this collaboration effort shows that refrigeration in the solid high efficiency state is not only scientifically viable but made on a large scale,” said Susan Ehrlich, head of marketing of APL technology. “We are impatiently awaiting research and continuous technology transfer opportunities with companies while we are working to translate these innovations into practical and real applications.”

Reference: “Thermoelectric materials with nano-designed thin layers allow practical refrigeration in the solid state” by Jake Ballard, Matthew Hubbard, Sung-Jin Jung, Vanessa Rojas, Richard Ung, Junwoo Suh, Minsoo Kim, Jonyhyun Lee, Jonathan M. Pierce Venkatas Nature communications.

DOI: 10.1038 / S41467-025-59698-Y

Never miss a breakthrough: join the Scitechdaily newsletter.