Unexpected equipment that could build our first March colony

Swinburne and Csiro Researchers have successfully produced iron under Mars type conditions, opening the door to the production of metals beyond the earth.

The vision of the establishment of colonies on March captured the imagination of billionaires, government’s space programs and defenders of space exploration.

However, the construction of these colonies requires large quantities of equipment, and transporting everything on the land is not practical. To put it in perspective, send NasaA rover of perseverance at one ton to Mars cost around $ 243 million.

Obviously, unless we plan to build a settlement adjustment only for ants, many more resources will be required. The challenge then becomes: how to get them?

For CSIRO Postdoctoral Fellow and a graduate of Swinburne, Dr DEDDY NABABAN, the solution can be in the own soil of Mars, known as Regolith.

“The sending of metals to Mars of the Earth could be possible, but it is not economical. Can you imagine bringing tons of metals to Mars? It’s just not practical, ”explains Dr. Nababan.

“Instead, we can use what is available on Mars. It is called the use of in situ resources, or isru. ”

More specifically, Dr. Nababan is considering astrometallurgy – manufacturing metals in space.

Build an outstanding foundry

It turns out that Mars has all the ingredients necessary to make native metals. This includes oxides rich in iron in the regolith and carbon of its thin atmosphere, which acts as a reducing agent.

The University of Swinburne of Astrométallurgist Technology, Professor Akbar Rhamdhani, works with Dr. Nababan to test this process with Simulant Regolith – an artificial recreation of what is found on Mars.

“We have chosen a simulating with properties very similar to those found at Gale Crater on Mars and treated them on earth with simulated March conditions. It gives us a good idea of how the process would work out of people, “he says.

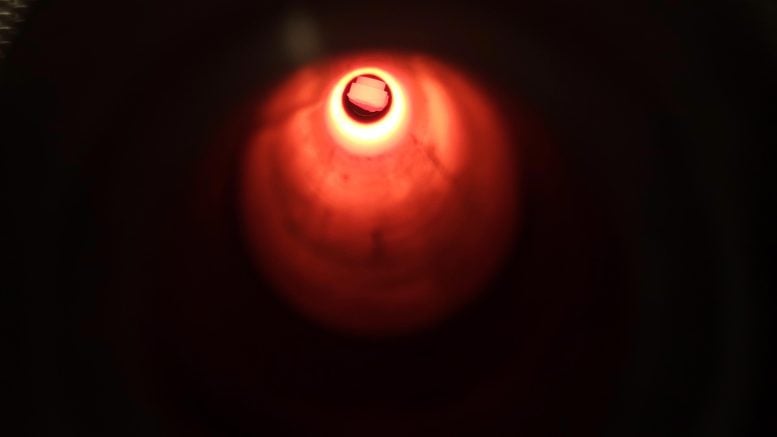

The simulating is placed inside a room at the surface pressure of Mars and heated at increasing temperatures. Experiments have shown pure iron metal formation around 1000 ° C, with liquid silicon alloys, iron produced around 1400 ° C.

“At sufficiently high temperatures, all the metals were merged into a large droplet. This could then be separated from liquid slag in the same way as on earth, “said Professor Rhamdhani.

With Dr. Nababan, Professor Rhamdhani collaborates with Dr. Mark Powceby of Csiro to advance the process. They are particularly focused on the manufacture of metals with zero waste, where process by-products are used to make useful elements.

If you cannot ship it, do it

In spatial exploration, the use of in situ resources (ISRU) becomes more and more important because each kilogram launched aboard a rocket adds to the cost and complexity of a mission. Although the launch costs gradually decrease, the extent of the resources necessary to support human exploration remains enormous.

Significant progress is already underway, including the first demonstration outside the world of the ISRU. The NASA Moxie experience, transported by Mars Perseverance Rover, has successfully generated oxygen breathing from anything more than carbon dioxide in the atmosphere of March.

Metal production is the next giant jump. Professor Rhamdhani hopes that alloys manufactured in March could be used as shells for housing or research facilities, and in machines for excavation.

“There are certainly challenges. We must better understand how these alloys would occur over time, and of course, if this process can be recreated on the real Martian surface, ”explains Professor Rhamdhani.

But in the meantime, Swinburne and his partners double. Professor Rhamdhani, as well as Dr. Nababan and Dr. Matt Shaw, another researcher from CSIRO and Alun Swinburne, recently presented a custom workshop of 4 days on astrometallurgy in South Korea. The comments were promising.

“We are starting to see an increased interest in this field on a global scale, because the world is serious about the exploration of March,” he said.

“To get there, we will need experts from many areas – mining, engineering, geology and much more.”

For Dr. Nababan, the advantages go beyond exploration. He hopes that their research will also lead to more effective metallurgy here on earth.

“By doing this, I want me to help the development of spatial exploration, and in the end, it will bring good life to human life here on earth.”

References:

“Iron (alloy) Extraction on Mars by carbothermal reduction of the regolith: a thermodynamic evaluation and an experimental study “by Deddy C. Nababan, Mark I. Powceby, Aaron Torpy and Mr. Akbar Rhamdhani, May 5, 2025, Astronautics.

DOI: 10.1016 / J.Actaastro.2025.05.005

“Extraction of metals on Mars by carbothermic reduction: Characterization of Mars Regolith simulating (MGS-1) and preliminary reduction” by Deddy C. Nababan, Mark I. Powceby and Mr. Akbar Rhamdhani, April 23, 2025, Astronautics.

DOI: 10.1016 / J.Actaastro.2025.04.050

Never miss a breakthrough: join the Scitechdaily newsletter.

:max_bytes(150000):strip_icc()/VWH-GettyImages-1763568954-856fe3cfc7574e408f0231dd97b47669.jpg?w=390&resize=390,220&ssl=1)

:max_bytes(150000):strip_icc()/Health-GettyImages-ThingsYouShouldntPutInAnAirFryer-577fafdb488b456399de0c8258915fc6.jpg?w=390&resize=390,220&ssl=1)